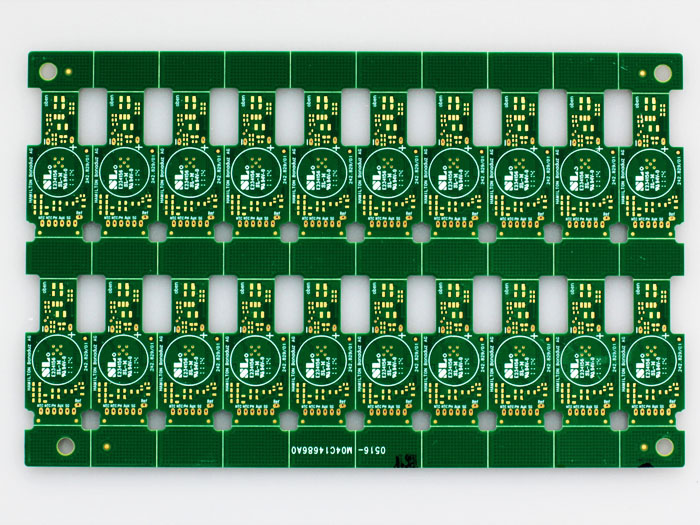

Why are High frequency PCB boards so popular?

What is HighfrequencyPCB?

Since wireless networks are growing as the best solution to communicate among devices, the high-frequency PCB (HFPCB) was needed with a special material used in electronic circuit boards to support high-frequency signals in communication electronics.

By checking its frequency range, we find that high-frequency PCB features 500MHz – 2GHz faster rates of signal flow (far better than standard/low-frequency PCBs), making it used in high-frequency wireless networks, including different types of communication systems. These systems are wireless networks, microwave, satellite communications and optical communications, used in various industries.

.jpg)

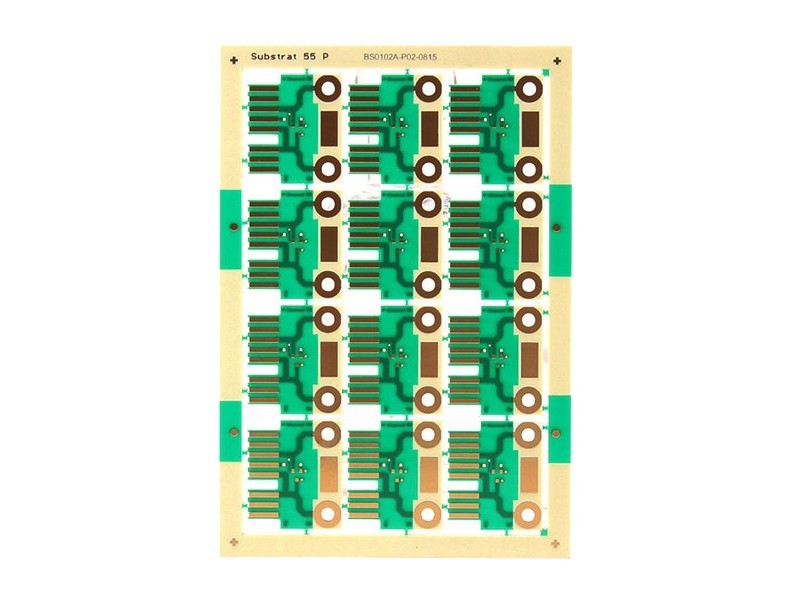

Features of high-frequency PCB

Following are the prominent features of high-frequency PCB:

Low Levels of Thermal Expansion

First of all, high-frequency PCBs are made from copper or aluminum, which are less prone to thermal expansion than other materials.This makes them suitable for applications that require precise temperature control and consistent performance.

Lower Dissipation Factor (DF) and Dielectric Constant (DK)

These PCBs have lower DF and DK than low-frequency ones, making them more durable and efficient as heat sinks for electronic equipment such as microprocessors and radio receivers.

Seamless Fins

They have a seamless construction with no gaps between the pins or pads, making them easier to sell than low-frequency PCBs that typically have a continuous surface patterning process with pin holes or vias drilled into each pad.

Environmental resistance

Last but most underrated feature, these PCBs have excellent environmental resistance, withstanding various chemicals and corrosive materials without damage to insulation layers or traces.

(2).jpg)

Advantages of high-frequency PCBs

FPCsupplier learned High-frequency PCBs are used as components in a variety of products, including high-power amplifiers and RFID tags.They have several advantages over low-frequency PCBs.

· More efficient use of energy resources

· Better signal quality and highly resistant to electromagnetic interference

· Higher bandwidth for higher data transmission rates

· Lower cost due to fewer layers

· Can be used in extremely harsh environments such as oil, gas and water

· Operate efficiently at high temperatures

· Used in advanced yet in-demand instruments

Where can high-frequency PCB be used?

High-frequency PCB is used in a variety of applications. Here are some examples of where they can be used:

· Electronics

Make electronics more efficient and fast.

· Telecommunications

Transmit data quickly between computers and cell phones over long distances.

· Medical equipment

Medical devices that need to send information quickly or have very precise control over their movements or settings.

· Industrial equipment

Used for industrial equipment like conveyor belts, forklifts and cranes that need high-speed movement without breaking down easily.

How is a high-frequency PCB manufactured?

PCB manufacturer China learned the high-frequency PCB manufacturing process involves a lot of steps.

Solder the PCB

The first step is to solder the PCB, which is done with a precious metal like gold. Then the board is tested for defects with an automated testing machine that reads the data from each electrical component on the board and compares it to the expected value.

Apply anti-static coating

The next step is to apply anti-static coating, which helps prevent static electricity from damaging your electronics. Anti-static coating also protects your board against corrosion by keeping moisture out of its surface.

Protect your board

After that you’ll need to protect your board from water damage by applying water-repellent lacquer or epoxy paint to it. Then you can ship it off to a manufacturer who will cut traces and connect components onto your PCB so that you can assemble and test them yourself!

Other news about S&L

- Celebrating the Establishment of SUNLYNN CIRCUITS(THAILAND)

- Good News! Sun&Lynn Circuits Co.,Ltd. is honored as one of the Top 100 Innovative Enterprises in Bao

- What Should You Know about Metal Core PCB

- FPC supplier : the types of Flexible PCB

- PCB manufacturer China:Why PCB board snake line, what is it used for?

- What is Metal Core PCB and types of Metal Core PCB?

- Why are High frequency PCBs much more expensive than normal PCBs?

- Flexible PCB supplier China :When to use flexible PCB?

- Flexible PCB manufacturer:What Is Flex Soldering?

- What Is Automotive PCB? Why we use automotive PCB?

Your browsing history

- PCB manufacturer China S&L visited Bourns to discuss new strategy in 2018

- FPC supplier:Types of FPC

- Flexible PCB manufacturer:How to distinguish FPC good or bad?

- Common Usage of a Metal Core PCB

- FPC manufacturer:What is Corrosion

- Health care PCB Factory Tells You What is a Cold Solder Joint

- Flexible PCB manufacturer:Why More and More Customers Choose FPCA One-Stop Service

- Beijing's optoelectronic co., LTD

- PCB factory china tells you what is Printed Circuit Board Prototype

- High frequency PCB:What makes it High frequency conducting circuit

A total of -comments【I want to comment】