PCB manufacturer China:What is PCB?

What is PCB?

PCBmanufacturerChina talk PCB is a copper laminated and non-conductive Printed Circuit Board, in which all electrical and electronic components are connected together in one common board with physical support for all components with base of board.

When PCB is not developed, at that time all components are connected with a wire which increases complexity and decreases reliability of the circuit, by this way we cannot make a very large circuit like motherboard. In PCB, all components are connected without wires, all components are connected internally, so it will reduce the complexity of the overall circuit design.

PCB is used to provide electricity and connectivity between the components, by which it functions the way it was designed. PCBs can be customised for any specifications to user requirements. It can be found in many electronics devices like; TV, Mobile, Digital camera, Computers parts like; Graphic cards, Motherboard, etc. It also used in many fields like; medical devices, industrial machinery, automotive industries, lighting, etc.

PCBsupplier talk Types of PCB:

There are several types of PCB available for the circuit. Out of these types of PCB, we have to choose the appropriate type of PCB according to our application.

Single-layer PCB

Double-layer PCB

Multi-layer PCB

Flexible PCB

Aluminium backed PCB

Flex-rigid PCB

Types of PCBs According to Mounting System

1) Through-hole PCB:

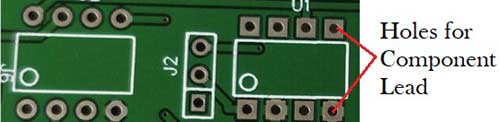

In this type of PCB, we have to make hole using drill on PCB. In these holes, leads of components are mounted and soldered to pads situated on opposite side of PCB. This technology is most useful because it gives more mechanical support to electrical components and very reliable technology for mounting of components but drilling in PCB make it more expensive. In single layer PCB, this mounting technology is easy to implement, but in case of double layer and multi-layer PCB making hole is more difficult.

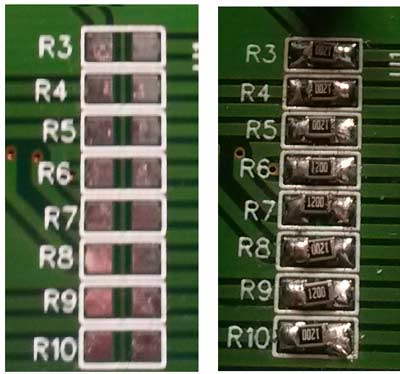

2) Surface mounted PCB:

In this type of PCB, components are small in size because these components have very small lead or no leads are required for mounting on the board. Here, in this technology, SMD components are directly mounted on the surface of the board and not require to make hole on board.

Other news about S&L

- Sun&Lynn Circuits CO., Ltd. was invited to attend the Sixth Global Customs AEO Conference!

- Celebrating the Establishment of SUNLYNN CIRCUITS(THAILAND)

- Good News! Sun&Lynn Circuits Co.,Ltd. is honored as one of the Top 100 Innovative Enterprises in Bao

- What Should You Know about Metal Core PCB

- FPC supplier : the types of Flexible PCB

- PCB manufacturer China:Why PCB board snake line, what is it used for?

- What is Metal Core PCB and types of Metal Core PCB?

- Why are High frequency PCBs much more expensive than normal PCBs?

- Flexible PCB supplier China :When to use flexible PCB?

- Flexible PCB manufacturer:What Is Flex Soldering?

Your browsing history

- PCB Solder Mask Colors in Flexible PCB manufacturer

- PCB supplier china:What is PCB?

- PCB factory china:The Modern PCB Design Methods

- 7 critical things of Selecting a PCB manufacturer China

- PCB manufacturer China:What is PCB Backplane Testing

- Flexible PCB supplier China :How to Judge Whether The FPC is Good or Bad?

- FPC supplier:Types of FPC

- CEIEC

- Applications and Types of Automotive PCBs for the Automotive Industry

- Automotive PCB manufacturer:What are the Internal Composition Layers of a PCB?

A total of -comments【I want to comment】